Q: What is Industrial CT? Industrial CT based on automotive parts?

Industrial CT is industrial computed tomography imaging, which can clearly, accurately and visually demonstrate the internal structure, composition, material and defective condition of the inspected object in the form of two-dimensional tomographic images or three-dimensional stereoscopic images without damage to the inspected object.

Industrial CT based on automotive component applicationsWith the increasing supply-side reform of the automotive industry, environmental protection to the national six emission standards, as well as the development and promotion of new energy vehicles, by the continued impact of trade friction between the United States and China and other industry status, forcing the rapid transformation and upgrading of the automotive industry.

The traditional automotive industry is based on industrial DR inspection of components, but the key components in the automotive industry need to add the application of industrial CT to meet the strict quality control of the automotive industry, process analysis and improvement, technology research and development and upgrading, the key components of the product defect type and size determination, the precise depth measurement of defects and porosity analysis report. (The corresponding standards are ASTM E505, VW50093, etc.)

Raysov, as a well-known domestic X-ray manufacturer, in industrial CT in recent years in the key technology breakthroughs and the rise of greatly reduced costs, mainly due to its breakthroughs and leading in the X-ray machine part of the high-frequency technology, ray machine from the low control accuracy, poor stability of the radiation dose of the frequency development of industrial frequency 50Hz to no less than 40KHz high frequency, so as to completely eradicate the drawbacks.

VG Studio series of three-dimensional reconstruction and analysis software in the domestic promotion, to ensure the absolute quality of the product and reduce the cost, so that the prospects for the popularization of industrial CT applications automotive industry is very optimistic.

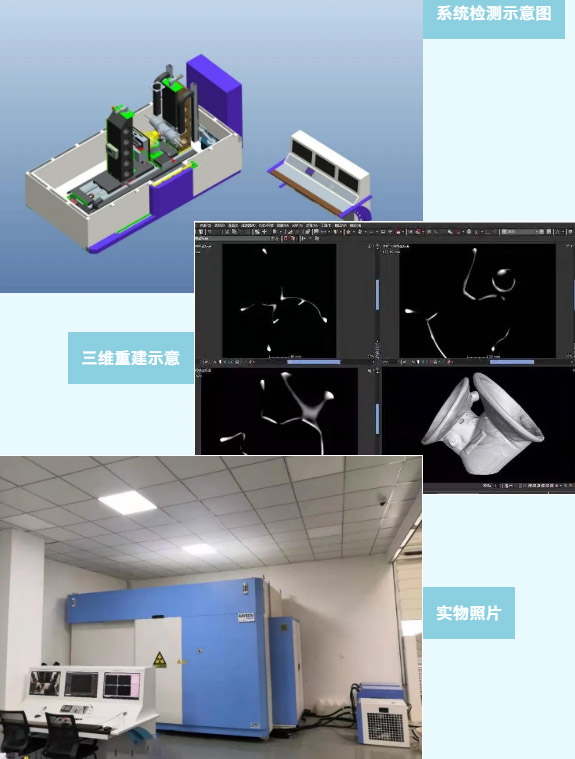

Industrial CT (Computed Tomography) technology development and advantage is not subject to the image of the surface condition of the workpiece, nor the image of the complexity of the internal structure, with the automotive industry for the quality of precision casting products more and more stringent requirements, industrial CT is also gradually promoted and applied, through the rotation of the workpiece to capture the two-dimensional image, and through the VG Studio software to reconstruct the three-dimensional model of the casting, to be able to precision The spatial location, defect type, size, porosity, etc. of the internal defects of the casting can be measured and analyzed.

Fundamentals:The industrial CT of auto parts is based on X-ray machine transmission, digital flat panel detector receiving signal and transmitting to computer workstation to complete image acquisition, rotating platform circumferential rotation to complete the rotational movement of auto parts, to meet the industrial CT in the form of two-dimensional tomographic images or three-dimensional images, clear, accurate and intuitive display of the structure, composition, material and defective condition of the inspected auto parts, belongs to the current It is the leading technology of non-destructive testing and non-destructive evaluation.

Solution:Based on high frequency X-ray machine, digital flat panel detector, workstation and image acquisition system and 3D reconstruction and analysis software, marble structure high-precision inspection platform, multi-axis electronically controlled motion system, lead protection system and monitoring system, etc.

The main scanning methods: cone beam CT scanning imaging, large field of view cone beam CT scanning imaging, spiral CT scanning imaging, etc.

Industrial CT plays a vital role in the quality control of automotive parts, maintaining high sensitivity indicators and spatial resolution in different cross-sections, and enabling precise localization and measurement of defects in products and porosity statistics and analysis of internal structures.

For product quality control, technical design, optimization and improvement are important, for the automotive manufacturing industry innovation and research and development to provide a strong technical support and quality assurance, so as to optimize the product manufacturing process, improve performance and service life, help the long-term healthy development of enterprises, industrial CT gradually popularized the application of automotive parts prospects worth looking forward to.

Write at the endRaysov (RAYSOV Instrument) (Raysov Instrument Co., Ltd), established in 2009, is a high-tech enterprise specializing in the development and manufacture of radiographic digital imaging systems (industrial DR, industrial CT) products and continuously providing customers with localized solutions.

Raysov people have been down-to-earth, continuous deep plowing technology, optimize the product, the product and technology these real ability as a means to resist fierce market competition, making Raysov is not only a well-known brand of domestic ray, but also domestic ray quality products.

At the end of the article, I also hope that the market for domestic ray detection instruments to give more opportunities and trust, domestic products need only a level playing field as well as a fair evaluation, in the new anti-epidemic era of 2022, imported products, manufacturing, production, transportation and other aspects of a substantial delay is the various types of production enterprises have to face, and this delay to our domestic manufacturing production and economic development have Adverse impact, so please choose stable and reliable domestic non-destructive testing equipment, please choose Raysov.