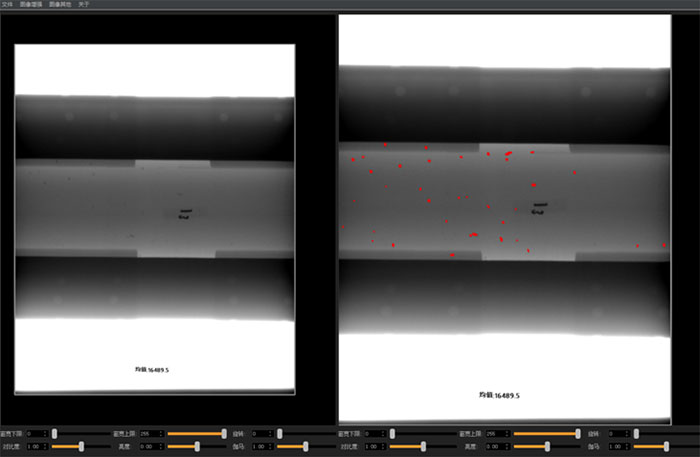

Automatic defect recognition effect

How to understand Automatic Defect Recognition ADR?

Automatic Defect Recognition, or ADR, is an algorithm that accomplishes recognition by training a neural network backwards and forwards.

The algorithm has the following main steps:

1、Manually screen multiple defective images for calibration of the data set for reverse sex training.

2、Construction of defect recognition model, reverse training of the labeled dataset, and automatic optimization of model parameters.

3, the model forward calculation of the new image, to get the new image defect recognition results (the above figure is the recognition effect through Raysov automatic defect recognition software).

What is the scope of ADR applicable to?

1. Casting defect detection under X-ray, automatic identification of air holes and slagging, etc.

2.Automatic identification of missing parts, wrong position, etc. under X-ray.

In the automotive manufacturing industry, product quality and safety and manufacturing cycle requirements are getting higher and higher. Automatic identification, accurate defect identification and efficient detection speed through ADR.

It can be applied to the detection and identification of steering knuckle/engine block/cylinder head/piston/brake disc/subframe, etc.

Technical advantages of Raysov Automatic Defect Recognition Software

1. Compared with the traditional forward comparison method of defect identification, ADR automatic defect identification software requires lower mechanical precision and higher accuracy.

2. Calculation through GPU, recognition speed is faster.

Raysov is committed to providing customers with reliable, efficient and intelligent X-ray visualization quality control solutions, and is favored by more and more customers for its excellent user experience and perfect detail design in the inspection fields of automotive wheels, shaped automotive parts, petroleum steel pipes, pressure vessel components, high-voltage electrical components, aerospace and weaponry.