Introduction to Castings

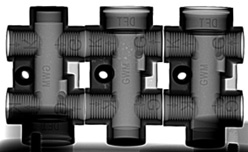

Introduction to CastingsCasting is the process of melting metal or its alloy, making a cast. The metal solution is poured into the mold, and after solidification of the metal solution, a metal part of a certain shape, size and properties is obtained in the form of a blank. Casting is one of the basic methods of workpiece forming, and is the most direct method of all metallurgical forming. However, there are many defects in the castings produced by casting.

The common internal defects in castings are divided into four major categories: hole defects, crack defects, inclusions, and defects in the formation of categories. These defects can be visually determined by X-ray inspection of the location, shape and size.

D-Series offline imaging inspection systems

Raysov D series offline real-time imaging inspection system (industrial digital imaging system, also known as industrial DR) is an X-ray flaw detection equipment for different sizes and dimensions of castings (aluminum alloy parts, steel alloy parts, titanium alloy parts, ceramic, graphite, resin and other composite parts) automotive parts and small and medium-sized welded parts (gas cylinders, steel cylinders, high-voltage electrical shells, etc.) to detect defects.

Do you want to know what are the differences between industrial DR/industrial CT and how to choose? Quickly click on the link.

Raysov , China Ray! To provide you with high quality industrial radiographic flaw detection products and a full range of non-destructive testing solutions!

Industry-leading Raysov high-frequency high-voltage generator, the core component of the X-ray machine, stable and reliable performance can completely replace imported brands;

Raysov self-developed image processing software to get a clearer and more intuitive detection images, detection images can be stored for a long time;

Excellent quality of equipment, unique craftsmanship, simple operation, efficient and convenient, stable and reliable;

Adopting the international advanced 5-axis mechanical movement mode to improve the detection efficiency and ensure the detection of 360 degrees without dead angle;

Safety higher than the industry standard, self-shielded equipment, leakage radiation dose less than 1μSv/h (national standard 2.5μSv/h);

Automatic fault alarm, a more intuitive display of the cause of failure, easy to repair and maintenance.

Equipment parameters:

Maximum inspection workpiece size: 600x600x1200mm

Transmittance thickness: 160KV: Fe 20mm / Al 100mm (static)

225KV: Fe 30mm / Al 150mm (static)

320KV: Fe 45mm / 40mm (static / dynamic) 450KV: Fe 60mm / 50mm (static / dynamic)

General Imaging Technology

Enhanced image

Safety:

1. Leakage ray dose is less than 1μSv/h (national standard 2.5μSv/h)

2. With lead door chain function (to ensure that the lead door is closed when the ray is opened, otherwise the ray cannot be opened)

3. Real-time monitoring of indicators, automatic fault alarm (and display the cause of failure)