Engine piston is one of the main parts of the engine, it and the piston ring, piston pin and other parts of the piston group, and the cylinder head and so on together to form the combustion chamber, bear the gas force and through the piston pin and connecting rod to transmit the power to the crankshaft, in order to complete the work of the internal combustion engine process.

The heart of the fuel system - the engine piston is usually made of silicon aluminum alloy, copper-nickel-magnesium-aluminum alloy, or other special cast and non-ferrous alloys. Pistons should ensure high strength, high steel, light weight, high thermal conductivity, resistance to high temperature, high pressure, corrosion, and adequate heat dissipation.

Deficiencies in any one of these will affect the quality of the engine piston and reduce the overall engine life.

Intuitive, significant and efficient quality inspection methods and nondestructive testing instruments are vital. Among various types of nondestructive testing equipment instruments, industrial X-ray machines are easy to operate and have excellent imaging effects, and are widely used in aviation, aerospace, weapons, railroads, automobiles, ships and other fields.

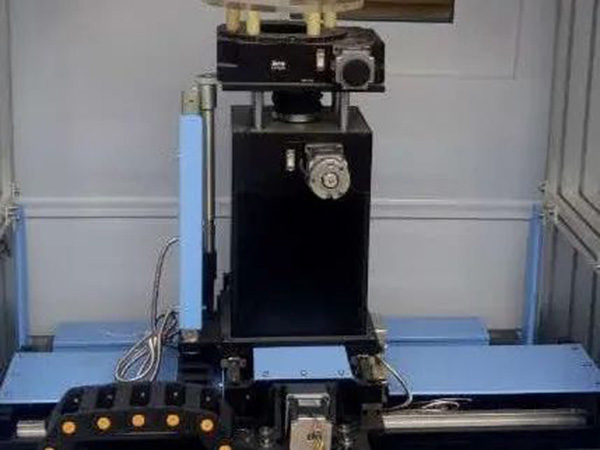

Raysov D type

Raysov's industrial X-ray real-time imaging inspection system for engine pistons (ZXFlaseeRaysov D series industrial DR or ZXVoxelRaysov industrial CT) applies the self-developed domestic industrial X-ray machine to the nondestructive inspection of engine pistons, which can be used for different specifications and sizes of castings (aluminum, steel, resin, etc.) and The series of products can be developed for different sizes and dimensions of castings (aluminum, steel, resin, etc.) and small and medium-sized welded parts high-end quality control and analysis needs, summing up years of application experience, and subdivision of the development of a series of inspection systems.

Industrial DR

Raysov's industrial X-ray real-time imaging inspection system for engine pistons (ZXFlaseeRaysov D series industrial DR or ZXVoxelRaysov industrial CT) applies the self-developed domestic industrial X-ray machine to the nondestructive inspection of engine pistons, which can be used for different specifications and sizes of castings (aluminum, steel, resin, etc.) and The series of products can be developed for different sizes and dimensions of castings (aluminum, steel, resin, etc.) and small and medium-sized welded parts high-end quality control and analysis needs, summing up years of application experience, and subdivision of the development of a series of inspection systems.

Raysov industrial ray specialist

ZXFlaseeRaysov Fuze D series industrial DR or ZXVoxel Rexin industrial CT can also be used for engine, piston ring, connecting rod, brake system, and also for other automotive parts inspection, which can be said to be an indispensable inspection equipment for automotive parts quality inspection.