The welding process has played an important role in production life since its inception and covers almost all industrial sectors, such as construction, heavy industry, vehicles, ships, aerospace, etc. However, defects from the inside and outside of the weld can affect proper operation and compromise quality. The quality of the weld becomes one of the key factors in product quality control. Therefore weld seam flaw detection is crucial.

Non-destructive testing radiographic inspection is the use of X-ray source to emit rays, penetrate the weld, and after software processing, display its internal defect image, is a more widely used nondestructive inspection methods, can find the internal weld porosity, cracks, slag, unfused, not welded through and other defects.

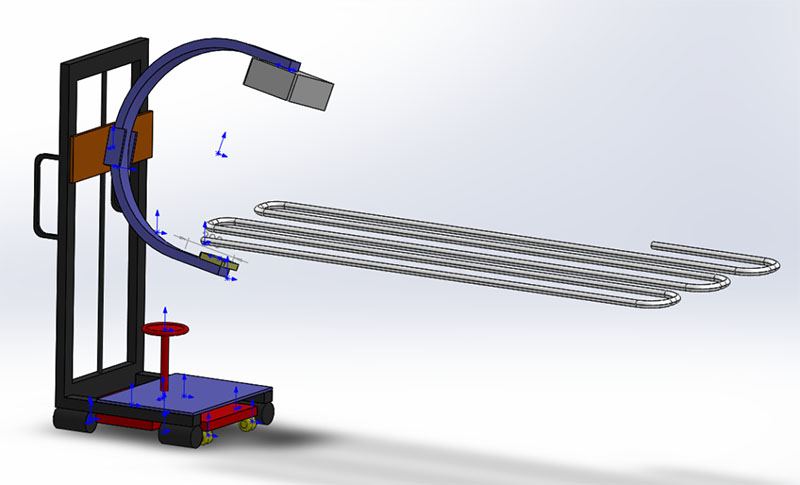

Raysov B series small diameter weld X-ray digital imaging inspection system

Raysov B series small diameter weld X-ray digital imaging inspection systemRaysov B-Series small-diameter weld X-ray digital imaging inspection systems are available for single-pipe and plate-tube weld seams to meet customers' diverse quality control needs.