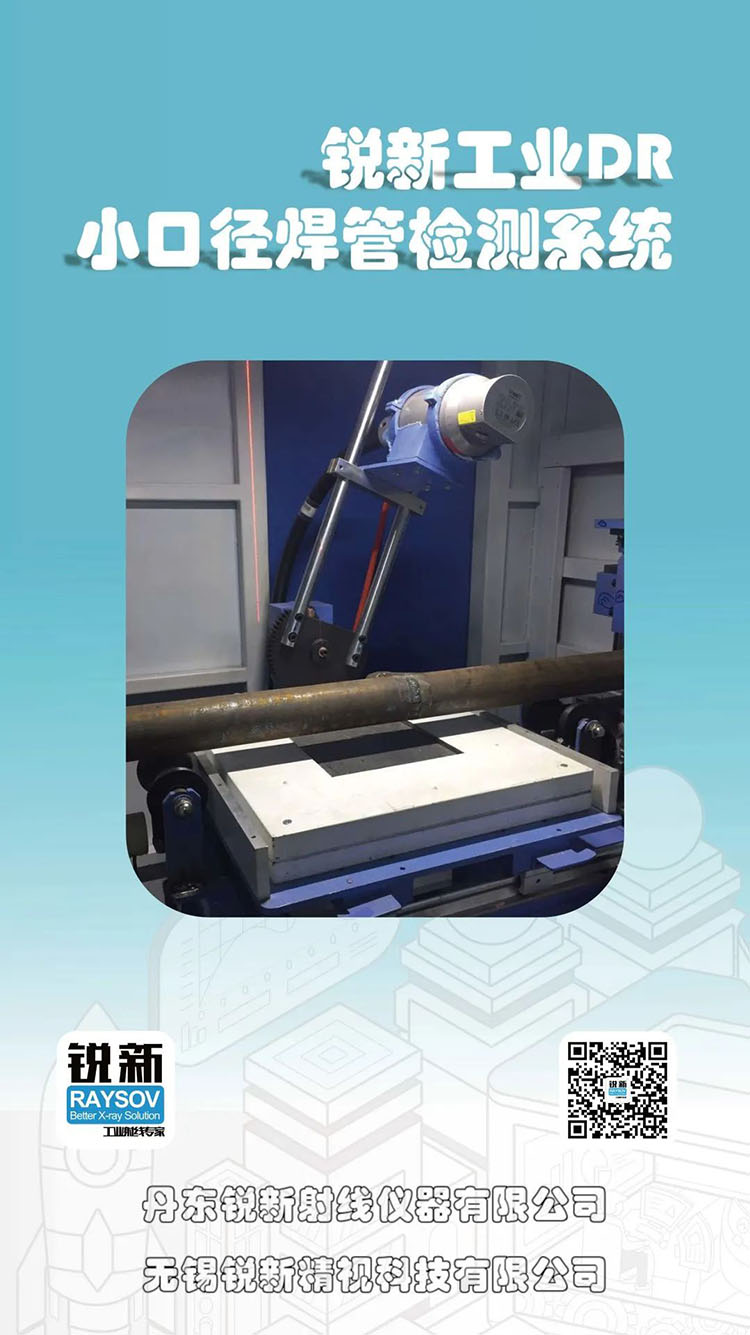

Introduction to small diameter welded pipe

Small diameter welded pipe is a steel pipe made of steel plate or strip steel that has been rolled and formed and welded.

Small diameter welded pipe production process is simple, high production efficiency, a variety of specifications, less equipment capital, but the general strength is lower than seamless steel pipe. With the rapid development of high quality strip steel rolling production and welding and inspection technology advances, the quality of the welded seam continues to improve, the increasing variety of small diameter welded pipe specifications, welded steel pipe according to the form of welded seam is divided into straight seam welded pipe and spiral welded pipe.

Weld quality has become an important factor affecting the quality of welded pipe, so weld flaw detection is essential.

Weld flaw detection testing is the detection of cracks or defects inside the product. It is a means of testing the surface and internal quality of the inspected product to detect the presence of defects or inhomogeneities in the inspected product without damaging or affecting the performance of the inspected object in use.

Common weld defects include, but are not limited to: porosity, cracks, slag, unfused, not welded through, etc.

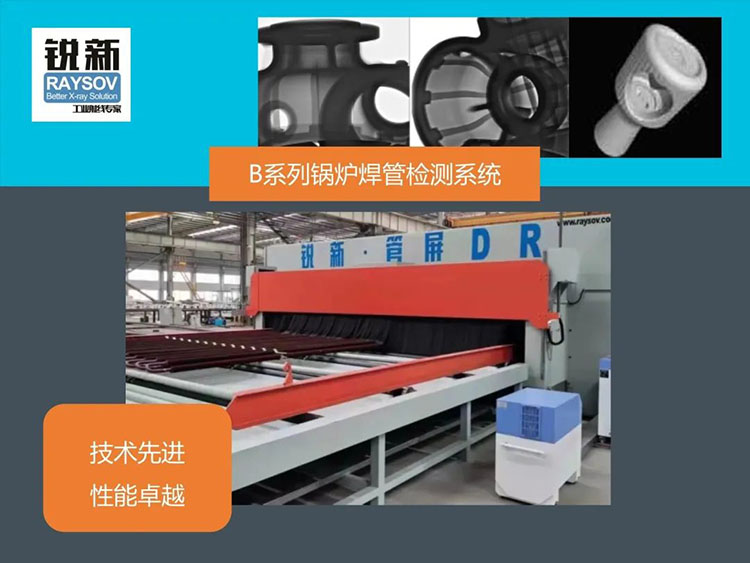

Raysov Ray B Series

Raysov Ray B SeriesThe Raysov B-Series offers several different types of inspection systems for single tube welds and row tube welds to meet the diverse quality control needs of our customers.

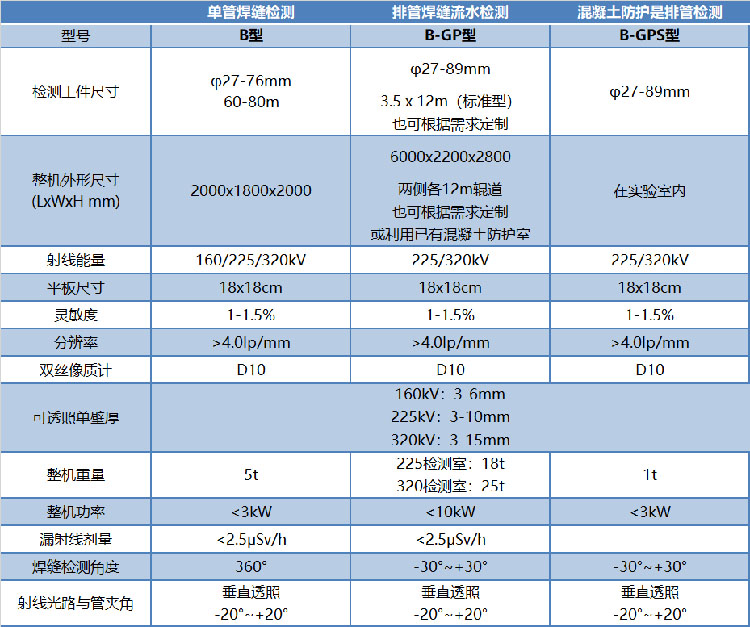

Selection table

Selection table