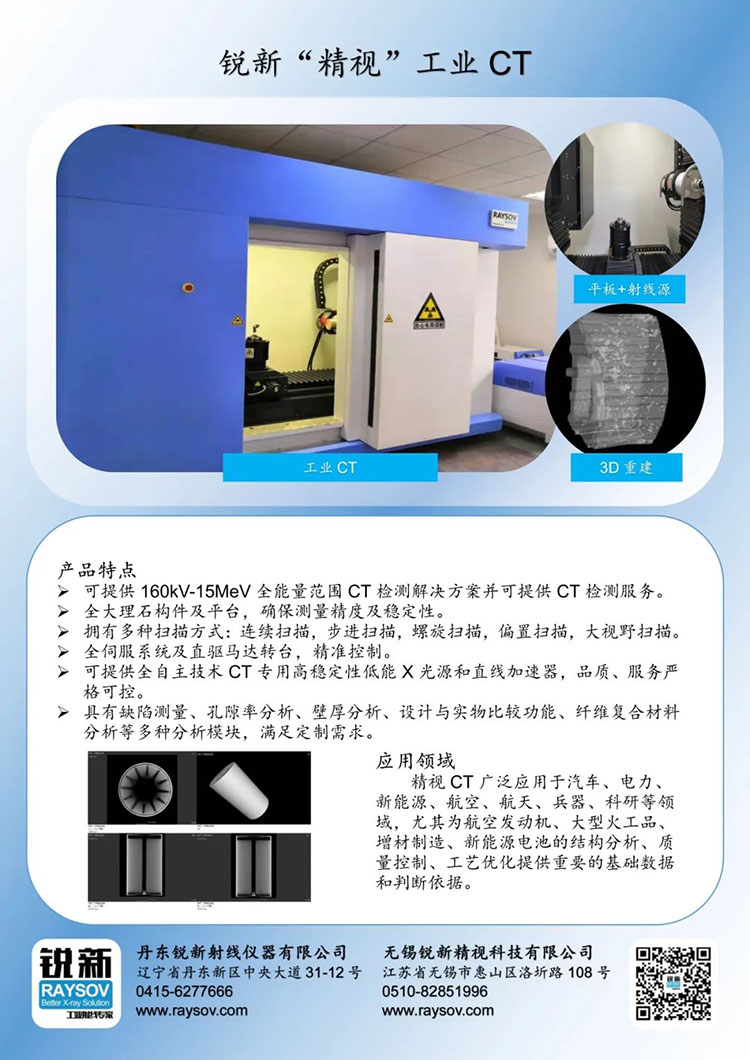

Industrial CT

Features of Raysov's industrial CTsCT inspection solutions and CT inspection services are available for the full energy range of 160kV-15MeV.

All-marble components and platform to ensure measurement accuracy and stability.

Multiple scanning modes: continuous scanning, step scanning, helical scanning, offset scanning, large field of view scanning.

Full servo system and direct-drive motorized rotary table for precise control.

Can provide all independent technology CT special high-stability low-energy X-ray source and linear gas pedal, quality and service can be strictly controlled.

With defect measurement, porosity analysis, wall thickness analysis, design and physical comparison function, fiber composite material analysis and other analysis modules to meet customized needs.

Fields of applicationPrecision Vision CT is widely used in automotive, electric power, new energy, aviation, aerospace, weapons, scientific research and other fields, especially for aero-engine, large-scale pyrotechnic products, additive manufacturing, new energy batteries, structural analysis, quality control, process optimization to provide important basic data and judgment basis.

Industrial CT is a kind of computerized tomography imaging technology, tomography independent imaging, to avoid unnecessary influence and interference, high image quality, can clearly and accurately show the measured part of the internal structural relationship, material composition and defect analysis. In the precision workpiece internal pores, bubbles, etc., high-end composite materials within the extrusion deformation, interlayer delamination and other defects detection, industrial CT inspection technology is a hundred changes in the small hands, has an indispensable role. Efficient, accurate, intuitive to find the type of internal defects, the specific location and size of the product, such as crack size, the location of air holes, etc., and analyze, find out the root cause of defects, and then improve the performance of the inspected product to extend its service life.

The Raysov X-ray industrial CT inspection system has been developed to meet the needs of high-end quality control and analysis of casting composites of different sizes and specifications, based on many years of application experience.

Optimized price/performance ratio for each application

Minimum nanometer focus available

Adopt German VGstudio 3D visualization and analysis technology

Full marble stage for high precision and repeatability

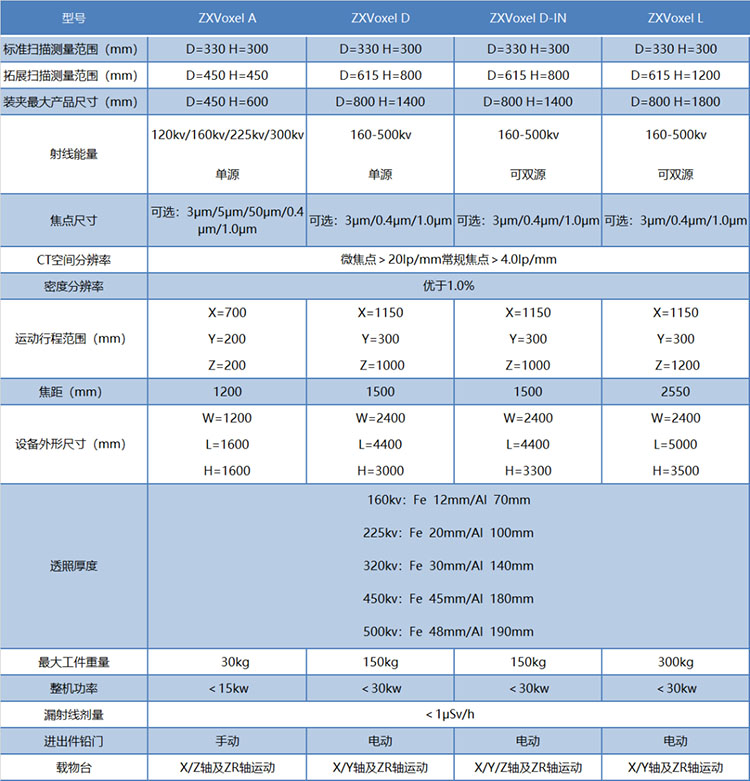

Selection Chart